Regularised vs Sawn Carcassing: Which Should You Choose?

The choice between regularised (machined) and sawn timber affects your project’s cost, installation speed, finish quality, and dimensional accuracy. Neither option is universally “better”—the right choice depends on your specific application, budget, and quality requirements.

This guide compares regularised and sawn carcassing timber across all key factors, explains when each type is the most appropriate choice, and helps you make informed purchasing decisions that balance cost against performance.

What’s the Difference? Regularised vs Sawn Timber Explained

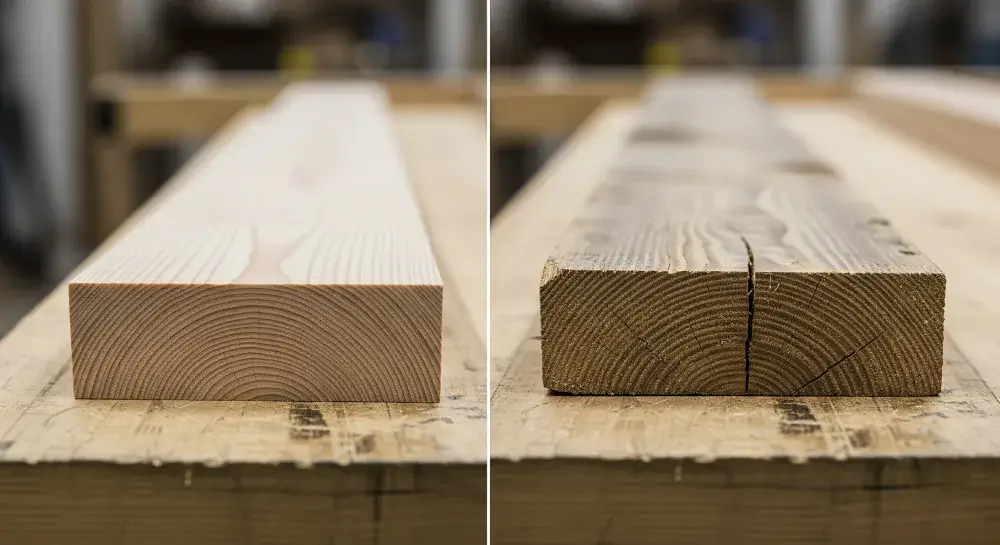

Sawn Timber (Rough-Sawn)

Sawn timber comes directly from the sawmill with minimal processing:

- Surface: Rough-sawn faces with visible saw marks and texture

- Edges: Sharp, unfinished edges that can splinter

- Dimensions: Close to nominal size but with natural variation piece-to-piece

- Consistency: Each piece varies slightly in cross-section along its length

- Processing: Minimal—just sawn to approximate size and dried (if kiln-dried)

Regularised Timber (Machined/Planed)

Regularised timber undergoes additional machining after initial sawing:

- Surface: Smooth, planed faces on all four sides

- Edges: Eased (slightly rounded) edges for safer handling

- Dimensions: Consistent finished size, smaller than nominal due to material removal

- Consistency: Uniform cross-section maintained along the full length

- Processing: Machined through planers to achieve consistent dimensions and smooth finish

View our regularised timber range →

Complete Comparison: Regularised vs Sawn Timber

| Factor | Regularised Timber | Sawn Timber |

|---|---|---|

| Surface finish | Smooth, planed faces on all sides | Rough-sawn with saw marks and texture |

| Edge treatment | Eased (rounded) edges, reduced splinter risk | Sharp edges, higher splinter risk |

| Dimensional accuracy | High—consistent piece-to-piece (±1-2mm typical) | Lower—variation between pieces (±3-5mm typical) |

| Finished size vs nominal | Smaller (typically 2-3mm thinner, 4-6mm narrower) | Closer to nominal size |

| Section depth | Reduced due to machining | Maximum depth retained |

| Installation speed | Faster—consistent sizing speeds up set-out and fitting | Slower—variation requires adjustment and scribing |

| Ease of handling | Easier—smooth surfaces, eased edges | Rougher—sharp edges, more splinters |

| Matching sheet materials | Excellent—predictable dimensions for panel cutting | Poorer—variation complicates panel fitting |

| Visible finish quality | Better—cleaner appearance if exposed | Rustic—acceptable for hidden or agricultural work |

| Painting/decorating | Less prep needed—smooth substrate | More prep—requires planing or heavy sanding |

| Typical moisture content | Often kiln-dried (16-20% MC) | Variable—can be green, air-dried, or kiln-dried |

| Movement after installation | Usually less (if kiln-dried), but still moves with moisture | Can be significant if supplied green or wet |

| Typical cost | Higher (10-25% premium depending on size) | Lower—minimal processing reduces cost |

| Labour cost impact | Lower—faster installation offsets material premium | Higher—additional time for adjustment and fitting |

| Wastage | Lower—predictable sizing reduces cutting errors | Higher—variation leads to more sorting and waste |

When to Choose Regularised Timber

Regularised timber is the better choice when:

1. Dimensional Accuracy Matters

- Stud walls and partitions where consistent wall thickness ensures plasterboard fits first time

- Floor and ceiling joists where uniform depth creates level surfaces without packing and shimming

- Working with sheet materials (OSB, plywood, plasterboard) where predictable framing dimensions simplify cutting and fitting

- Engineered connections such as joist hangers, timber connectors, or metal brackets designed for specific timber sizes

2. Installation Speed Is a Priority

- Commercial projects on tight schedules where labour time is expensive

- Large residential builds where consistent sizing speeds up framing crews

- DIY projects where ease of installation matters more than material cost savings

- Projects with inexperienced labour where dimensional consistency reduces errors

3. Finish Quality Matters

- Exposed framing in open-plan designs, vaulted ceilings, or feature structures

- Painted or stained timber where smooth surfaces reduce preparation time

- Built-in joinery such as cupboard frames, shelving, or utility room framing

- Semi-visible work where the cleaner finish improves perceived quality

4. Safety and Handling

- Environments with inexperienced workers or DIYers where eased edges reduce injury risk

- High-volume handling where smooth timber reduces splinters and handling fatigue

- Sites with strict H&S requirements where material handling safety is scrutinized

Browse our regularised timber products →

When to Choose Sawn Timber

Sawn timber is the better choice when:

1. Maximum Section Depth Is Required

- Structural applications where every millimetre of depth matters for span or load capacity

- Retrofit work matching existing sawn timber sections in older buildings

- Situations where you’ll plane on site to achieve custom dimensions or finishes

2. Budget Is the Primary Concern

- Large agricultural buildings where rougher finish is acceptable and cost savings are significant

- Temporary structures such as site huts, scaffolding supports, or formwork

- Hidden structural work where finish quality doesn’t matter (sub-floor joists, concealed roof framing)

- Projects with tight margins where the 10-25% material cost saving outweighs labour considerations

3. Finish Doesn’t Matter

- External framing that will be fully clad (timber-frame walls with breather membrane and cladding)

- Agricultural and utility buildings where function trumps appearance

- Structural work completely hidden by finishes (ceiling joists above plasterboard, floor joists under flooring)

- Workshop or industrial settings where rustic appearance is acceptable or even preferred

4. Traditional or Rustic Aesthetic

- Barn conversions where rough-sawn timber maintains character

- Traditional agricultural buildings being restored to original appearance

- Garden structures where rustic finish suits the setting (log stores, open sheds)

Cost Analysis: Total Installed Cost Matters More Than Timber Price

When comparing regularised and sawn timber, consider the total installed cost, not just the material price per linear metre.

Example Scenario: 100m² Stud Wall Partition

| Cost Element | Regularised 4×2 | Sawn 4×2 |

|---|---|---|

| Timber material cost | £800 (200 studs @ £4.00/stud) | £700 (200 studs @ £3.50/stud) |

| Labour hours | 24 hours (faster set-out and fixing) | 28 hours (more adjustment/scribing) |

| Labour cost @ £25/hr | £600 | £700 |

| Material wastage | £40 (5% due to predictable sizing) | £70 (10% due to sorting/variation) |

| Plasterboard fitting time | Included (minimal adjustment needed) | +2 hours (£50) for shimming/packing uneven framing |

| Total installed cost | £1,440 | £1,520 |

Result: Despite regularised timber costing 14% more per piece, the total installed cost is £80 lower due to faster installation, less wastage, and easier finishing.

Key insight: For projects where dimensional accuracy matters (stud walls, joists, precision framing), regularised timber often delivers lower total cost even though the material itself is more expensive.

Moisture Content and Movement Considerations

Both regularised and sawn timber move with changes in moisture content, but their typical supply condition differs:

Regularised Timber

- Usually supplied kiln-dried to 16-20% moisture content

- Starts drier, so less initial movement expected

- Still moves as it reaches equilibrium with site conditions (typically 12-15% indoors)

- Expect 1-2mm shrinkage in width/thickness over first few months indoors

Sawn Timber

- Can be supplied green (25%+ MC), air-dried (20-24% MC), or kiln-dried (16-20% MC)

- If supplied green or wet, expect significant movement as it dries

- A 100mm wide sawn stud drying from 25% to 15% MC can shrink 3-4mm in width

- Movement risk is higher if moisture content at delivery isn’t specified/controlled

Best practice for both:

- Specify moisture content when ordering (target 16-20% for structural use)

- Store timber properly on site (flat, covered, off ground, with airflow)

- Allow acclimatisation before precision fitting (7-14 days in installation environment)

- Accept that all timber moves—design and detail to accommodate it

Mixing Regularised and Sawn Timber: When Is It Acceptable?

General rule: Don’t mix regularised and sawn timber in the same structural element or where dimensional consistency matters.

Never Mix When:

- Building stud walls—inconsistent wall thickness causes plasterboard fitting problems

- Installing joists—mixing creates uneven floor surfaces requiring excessive packing

- Roof framing where uniform rafter depth is needed for straight roof lines

- Any situation requiring precise alignment or matching to sheet materials

Acceptable to Mix When:

- Different structural elements (e.g., regularised floor joists with sawn roof rafters—they’re separate systems)

- Temporary vs permanent work (sawn timber for site huts, regularised for the building)

- Hidden vs visible framing (sawn for concealed sub-floor, regularised for exposed ceiling joists)

- Budget phasing (using what’s available while maintaining quality where it matters)

Availability and Lead Times

Regularised Timber

- Availability: Excellent for common sizes (4×2, 6×2, 8×2)

- Lead times: Usually immediate or next-day for stock sizes

- Custom sizes: May require ordering, especially in larger sections or uncommon lengths

Sawn Timber

- Availability: Very good—sawmills hold larger inventories of rough-sawn stock

- Lead times: Often immediate for standard structural sizes

- Custom milling: Easier to source non-standard dimensions from sawmills

Practical impact: For urgent jobs or unusual sizes, sawn timber may be available when regularised isn’t. For standard construction, both are readily available.

Common Mistakes When Choosing Between Regularised and Sawn

Mistake 1: Choosing Based Solely on Price Per Metre

The problem: Buying sawn timber because it’s £0.50 cheaper per stud, then spending extra hours adjusting and fitting.

The solution: Calculate total installed cost including labour, wastage, and downstream effects on follow-on trades.

Mistake 2: Using Regularised for Hidden Agricultural Work

The problem: Spending 20% extra on regularised timber for a barn interior that will never be seen.

The solution: Save money with sawn timber where finish doesn’t matter and dimensional variation is manageable.

Mistake 3: Using Sawn Timber for Precision Studwork

The problem: Trying to achieve flat, plumb walls with sawn studs that vary 5mm piece-to-piece.

The solution: Use regularised timber where dimensional accuracy directly affects quality and downstream trades.

Mistake 4: Assuming “Regularised = Better Quality”

The problem: Thinking regularised timber is inherently stronger or more durable than sawn.

The solution: Understand that “regularised” describes finish, not structural quality. Both can be C16/C24 graded. Both can be treated. Choose based on application needs, not perceived “quality.”

FAQ: Regularised vs Sawn Timber

Is regularised timber stronger than sawn timber?

No. Strength depends on timber grade (C16, C24), not whether it’s regularised or sawn. Both can be graded to the same strength class. Regularised timber is machined for dimensional consistency and smooth finish—it’s not inherently stronger. A C16 sawn joist and a C16 regularised joist of the same size have identical structural capacity.

Why is regularised timber more expensive?

Regularised timber costs more because it requires additional processing. After initial sawing, the timber is run through planers to machine all four sides smooth and create consistent dimensions. This machining removes material (reducing yield), requires specialized equipment, and adds labour time—all of which increase cost by 10-25% compared to sawn timber.

Can I use sawn timber for stud walls?

You can, but it’s not recommended for internal stud walls where dimensional consistency matters. Sawn timber’s piece-to-piece variation (±3-5mm typical) makes achieving flat, plumb walls difficult and complicates plasterboard fitting. Regularised timber’s consistent sizing makes studwork significantly faster and achieves better results. Sawn timber is more suitable for external framing that will be fully clad.

Do I need to plane sawn timber before using it?

Only if you need smooth faces for visible work or precise dimensions for engineered connections. For hidden structural work (covered by cladding, plasterboard, or flooring), sawn timber can be used as-supplied. If the timber will be painted, stained, or exposed, planing improves appearance and reduces preparation time.

Is regularised timber kiln-dried?

Usually, but not always. Most regularised carcassing timber is kiln-dried to 16-20% moisture content for dimensional stability. However, drying method and moisture content should be specified separately from whether timber is regularised or sawn. Always check the supplier specification for moisture content regardless of finish type.

Can I mix regularised and sawn timber in the same project?

Yes, but don’t mix them in the same structural element. Using regularised floor joists and sawn roof rafters is fine—they’re separate systems. Don’t mix regularised and sawn studs in the same wall or joists in the same floor, as the dimensional variation creates problems. Keep each structural element consistent.

Related Guides

- Regularised Timber Sizes: UK Guide to Nominal vs Finished Dimensions – Understanding actual dimensions when ordering regularised timber

- C16 vs C24 Timber: Which Strength Grade Do You Need? – Strength grading applies to both regularised and sawn timber

- Tanalised & Treated Carcassing Timber: Complete Protection Guide – Treatment options for both regularised and sawn timber

- Regularised Timber Category Page – Browse our complete regularised timber range

Need help choosing between regularised and sawn timber for your project? Contact Ryedale Timber on 07403 011246. We supply both regularised and sawn carcassing timber across North Yorkshire and East Yorkshire with expert advice on the right choice for your application and budget.